Fri Sep 1 '17 Announcement

over 7 years ago

– Fri, Sep 01, 2017 at 11:12:40 PM

Part 3 of 3

⸻Other Updates⸻

Operation: Boxes Assembly

[above] Before. Our flat, un-assembled, custom boxes (white) and our custom foam inserts in the big bags (black). Here we pick them up to get the assembly operation started.

[above] We set up stations for building boxes, stuffing in foam inserts, pressing in Magnet Wands, closing up the box, and then finally putting them into large brown boxes to be taken back to our manufacturers ready to be filled with Stickybones.

[above] Helping hands from family clad in blue Nitrile gloves. After we built each box, we stuffed each one with the custom foam inserts and your complimentary Magnet Wand. (We’re giving you one for free with each Stickybones for a limited time. (Until they are all gone—we only have a small quantity of free ones left as of now.)

[above] Stickybones boxes from floor to ceiling.

All Stickybones pre-ordered BEFORE this update will come in this box. However, we just ran out of them, so the rest will be packaged in a different box.

Box Assembly: AFTER. All of the custom boxes assembled and at our manufacturer's warehouse poised to be filled with Stickybones.

Performance Stages

These are completely done, wrapped and ready-to-go at our fulfillment house. A VERY LIMITED quantity of Stages are left. If you want one, you may want to pre-order it now as they will sell out soon.

[above] Two Stickybones trial samples on a Performance Stage with the Fly-Rig in the Kamehameha pose.

Pose Plates

These are 100% Done, wrapped, and at our manufacturer awaiting Stickybones. One will be placed into each box of Stickybones just before it’s sealed.

Custom Materials

We’ve customized strong and durable materials so your Stickybones will be around to inspire you for years to come. All our custom materials have been created in quantity and delivered to our manufacturer. They're ready for the production run where they’ll be magically transformed into Stickybones and Fly-Rigs.

Thanks for making it to the end of our lengthy update. In conclusion, we are animators who left animation jobs we loved at amazing animation studios to create Stickybones—and while this journey has certainly been incredibly challenging and an exercise in endurance, we remain energized and ecstatic knowing that, once finished, the poses you will be able to achieve will only be limited by your imagination. (...and maybe a few laws of physics, but we digress...)

Happy Labor Day Weekend,

Team Stickybones

Fri Sep 1 '17 Announcement

over 7 years ago

– Fri, Sep 01, 2017 at 11:12:22 PM

Part 2 of 3

TRIAL SAMPLES

[above] 1st FULL Trial Sample that was good enough to get basic poses. [No magnets installed.] When we saw this sample, we were pleased to finally have the full molded character in hand, however we had to give many notes to the mold makers.

[above] The next iteration was even closer.

When we saw this next version, while it was better, only some of our previous notes had been successfully addressed, and many other notes were not addressed at all--So we had to give plenty more notes.

And now we’re onto the CURRENT YELLOW iteration.

The yellow is the closest Stickybones trial sample we’ve seen yet. It's ALMOST correct.Why can’t we just ship this version? Because a handful of joints are too loose and another is much too tight. Therefore you wouldn't be able to hit and hold the FULL RANGE of poses. We’ve communicated our notes to the mold maker and are waiting to see a GREEN version next.

[above] Lower left Stickybones is casually ignoring gravity on an outdoor pipe. No climbing-gear required.

[above] Getting these circus-inspired tandem poses were fast, easy and fun. (Which has always been our aim.)

When can we begin shipping?

We’re in an incredibly challenging spot right now. We really need to see the next GREEN sample to know where our molds stand. When the mold maker completes our molds, our manufacturer will be able to provide us with a production schedule that will outline our efforts to get these Stickybones out to everyone as quickly as we possibly can. That being said, as time marches on, it’s now becoming likely, however, that shipping won’t begin before November. But it could also be later if there are multiple notes left unaddressed. It still all hinges on the molds. For this uncertainty, we sincerely apologize. We know some of you have been waiting patiently for what must feel like eternity.

Once the molds are complete, our manufacturers will inspect them and begin the production run. We’ll then box them up and start shipping immediately.

We’ve been battling to have our molds correctly completed for a long while now, and as you can see from the photos, we’re so close to the finish line.

We really appreciated a nice message we got today from one of our earliest backers with this photo attached.

(Thank you, Moshe! Giving up isn’t in our vocabulary.) The world can never get too much positivity and encouragement⸻or mice wearing tiny helmets. Yes, please.

Fri Sep 1 '17 Announcement

over 7 years ago

– Fri, Sep 01, 2017 at 11:12:03 PM

Part 1 of 3

Message from Stickybones’ CEO:

Greetings,

Progress to share and developments to bring to your attention. We’ve assembled exciting images of our latest Stickybones samples, demonstrating some of Stickybones’ capabilities.

First, though, for those of you who have been with us on this journey for a long while now, we truly apologize for the delays. Unfortunately, and to all of our great frustration, we have missed previous ship-date targets because, simply put, the mold-makers did not meet deadlines.

However, we have now made significant progress with the molds. I continue to personally ensure our Stickybones specifications are met by putting every ounce of effort into reviewing, measuring, testing, creating detailed notes, and diligently and consistently communicating what specifically needs to be implemented to ensure the mold-maker gets the job done correctly.

Co-Founder, Lauren Baker finds invaluable solutions to work through the many challenges we’ve faced due to moldmaking delays. Countless hours and effort have been put toward keeping an open line of email communication with our backers as well as responding to comments, and launching and maintaining Instagram (a backer request) and other social media. She also presses forward with a multitude of vendor-related activities to keep our progress moving in the right direction in the effort to expedite shipment and successful delivery of Stickybones to all of our amazing backers throughout 96 countries to date.

We are fighting the fight and the finish line is in sight. I wholeheartedly thank you for believing in us and in Stickybones.

Best Regards,

Erik Baker

CEO/Co-Founder

Stickybones Update

Here's a look at the latest Stickybones Samples from our molds. Click for turntables:

[Note—The 2-tone Stickybones you see in links above and images below are trial samples only that don't show fingers—which will still come as expected. The Indiegogo production run of Stickybones will be single-tone colors (Dark Storm and Spark Blue. See them here.]

What’s left to do on the steel molds?

Our mold maker is working to meet our specifications on a few more of the joints. For example, one joint is far too tight and a handful of others are too loose (this includes fingers.)

The following series of photos are various Trial Samples as we’ve honed in toward completion.

Thu May 18 '17 Announcement

over 7 years ago

– Thu, May 18, 2017 at 03:05:20 PM

May 18—Part 2 of 2

Custom Stickybones Materials

The Big News: We’ve received our Color Check-Color Chips made in our actual custom materials. Our material partners are creating large batches and will send them to our Stickybones manufacturer.

Photo: In direct sunlight is Chroma Key Green, Spark Blue & Dark Storm in our final material.

Stickybones Figures

Progress!!! In the photo below, this Stickybones figure you see is comprised of our trial manufactured parts from our steel molds (the white parts and the hands) and our prototype parts (the black parts.) As we mentioned in our last update, our mold-maker is retooling a few of the parts into the steel molds, like the head, feet and fingers. We expect to see samples from those new cavities soon.

The Big News: We have many more Stickybones parts to show! Our mold-maker continues to refine all of our steel molds, working through a punch-list of notes that must be addressed. All parts are still “rough around the edges” and are still in the process of being further refined and "dialed-in." As stated before, our parts are very complex from a molding standpoint, so while our mold-maker is making good progress, the completion of the molds continue to take them longer than they anticipated and estimated for us. Because of this, we've decided to add even more people and more resources to our moldmaking team to help expedite the completion of this giant process. We're putting all of our resources and energy into pushing the molds along for the fastest results possible while keeping a close eye on quality. For shipping, our schedule does hinge on when the molds complete. The moment they're done, we'll make the parts, assemble them, box them, and send them to our fulfillment house to immediately ship out to you. We'll keep you posted as we refine and see more Stickybones trial parts and near finalization.

Magnet Wands

The Big News: All Magnet Wands are DONE and delivered to our SB manufacturer. They are beautiful! We took an extra step of nickel plating them to prevent rusting and give a pretty finish.

The Next Step: One Magnet Wand will be placed into each box of Stickybones. We’ve designed a special little nook in the foam insert to keep the Magnet Wand snugly in place.

Photos Top starting left: 1.)The evolution of our Magnet Wand prototypes using both metal machining and 3D printing. 2.) Pile of finished Wands. [Bottom] 3.) Finished Magnet Wands that can double as bowling pins for hamsters. 4.) he final Magnet Wand!

Thu May 18 '17 Announcement

over 7 years ago

– Thu, May 18, 2017 at 03:04:34 PM

May 18—Part 1 of 2

A Multitude of Greetings,

Another update with lots to share! (For more frequent updates, follow us on Instagram!)

Packaging: CUSTOM BOX

The Big News: Our custom Stickybones boxes are DONE!!! We geared up in yellow vests and hard hats to witness the massive printing and die-cutting machines churn out our boxes with speed and ease! With ink buckets bubbling, rollers rolling, pistons churning, and noises whirring and clanking--it was an exciting sight to behold!

The Next Step: The flat boxes have already been delivered to our Stickybones manufacturer and are ready to be folded into box-form

Check out this VIDEO (33 sec) of our custom Stickybones boxes being made at the factory!!

Photos top row starting left: 1.) Checking the color Pantone 2.) Erik signing off for box approval--time to start running them! 3.) Gearing up to go onto the factory floor. Bottom Row: 4.) Our cardboard box before being printed, die-cut, and folded. 5.) Our special color in liquid ink form. 6.) The die-cutting machine with our custom attachment to cut the shape of our box.

Packaging: CUSTOM FOAM INSERT

The Big News: The custom Foam Inserts are DONE and have already been shipped to our Stickybones manufacturer.

The Next Step: They’ll each be placed into a Custom Stickybones box and will be ready to do what they were born to do: Snuggle a Stickybones!

Performance Stages

The Big News: 95% of the Performance Stages are finished and wrapped for shipping.

The Next Step: We have created Performance Stage UPC label stickers and are in the middle of placing one sticker on each Stage. Once done, the whole lot of them will be delivered to our fulfillment house, ready to ship.

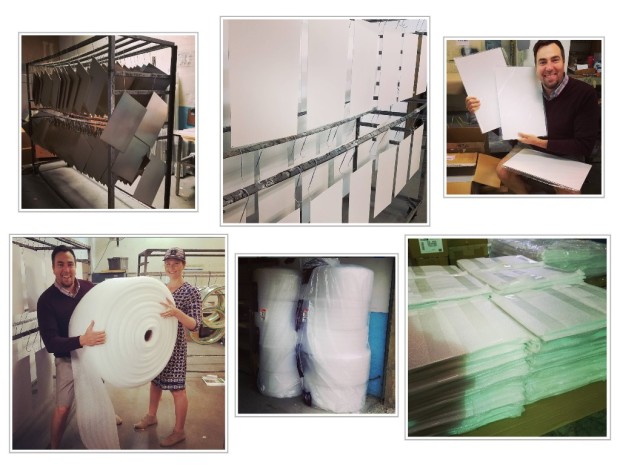

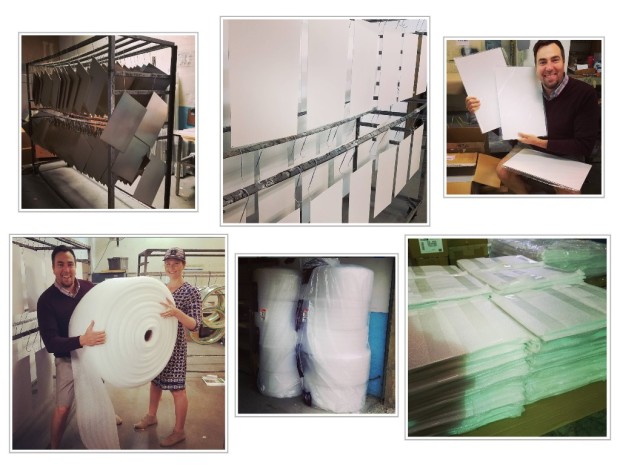

Photos top row starting left: 1.) Raw steel Performance Stages cleaned and awaiting paint. 2.) Freshly powder coated stages. 3.) Erik holding some finished stages that have been sealed into individual bags. Bottom Row: 4.) Erik and Lauren holding a massive foam roll for wrapping the stages for shipping. 5.) More massive foam rolls--each one is 6 feet tall. 6.) Stacks and stacks of stages each sealed into a bag and then wrapped up for shipping.

Pose Plates:

The Big News: The Pose Plates are also 95% done!

The Next Step: Finish painting and bagging the final 5% and ship them to our Stickybones manufacturer.

Photo: Boxes of finished pose plates sealed in individual bags.

(Please continue to Update Part 2 of 2)