Sat Apr 8 '17 Announcement

over 7 years ago

– Sat, Apr 08, 2017 at 06:05:47 PM

Mar 8—Part 3 of 3

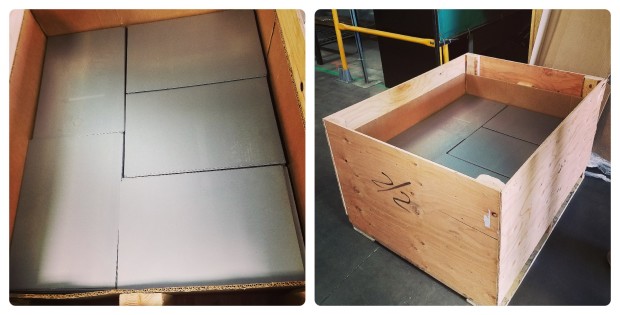

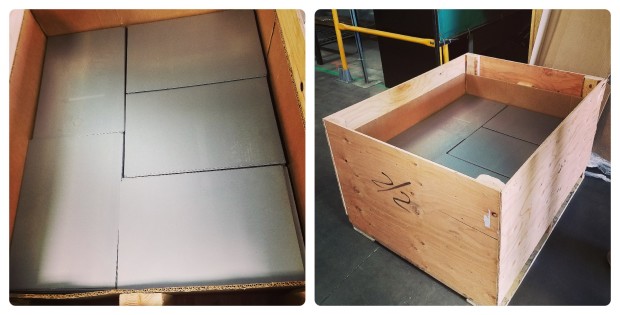

Packaging/Stickybones Box

The Big News: Stickybones boxes are being manufactured NOW! Below is the foam insert we designed to cradle Stickybones. We worked hard to get the foam cut just right. Also here is the final packaging artwork—We had fun with the layout and graphics, beginning the process with paper cut outs, then transferring the designs into 3D renderings for more exploration. Once done, we put them into a vector format and sent them to our packaging partners.

The Next Step: Once the packaging is manufactured, it'll be shipped to our Stickybones manufacturer.

Material Colors

The Big News: Our material partners are creating our color formulas now: Dark Storm, Limited Edition Spark Blue, and Chroma-Key Green (Fly-Rig.)

The Next Step: They're sending us physical color chips for approval, which we expect to receive next week.

The Learning Curve:

At Stickybones, we are first and foremost professional animators. We are approaching this product with passion, love and dedication to create the best tool we possibly can for our art and animation communities (and beyond.) We’ve learned so much venturing from the world of animation into the vastly different world of high-precision engineering and manufacturing. Yes, the amount of work it takes to do something like this is staggering—but we're doing this because we believe in the usefulness of Stickybones and we are SO EXCITED to see all the fun and creativity Stickybones will inspire. If we could do the entire campaign over again, we'd add a great deal more time-padding to the schedule. Stickybones is a very complex product to manufacture because nothing quite like it has ever been done —even our toolmaker vastly underestimated the amount of time it would take to make our molds.

Our entire manufacturing team greatly values everything we’ve learned along the way, and this knowledge and experience will be put into creating future Stickybones much faster!

Flipbook Animation Kit

A member of our Stickybones backer community (and a stop-motion animator at Laika) has a Kickstarter Campaign right now called Flipbook Animation Kit. We're sure this would interest many members of our community. Check it out today—there are only 9 days left! CLICK HERE.

The Flip Book Animation Kit will give you everything you need to make your own animated flip book cartoons!

This could be a fun, complementary product to use with Stickybones. We’ve pre-ordered ours and can't wait to create with it!

Sat Apr 8 '17 Announcement

over 7 years ago

– Sat, Apr 08, 2017 at 06:05:27 PM

Mar 8—Part 2 of 3

Stickybones

The Big News: We’ve inspected the first trial samples from our manufacturer. There are a total of 39 unique molded parts for Stickybones. We gave detailed notes on all of these parts and are awaiting the second trial samples for further inspection and testing. These are scheduled to complete next week. During the inspection of our first trial samples we found a few parts that didn’t meet our specifications—We’ve spoken in depth with our manufacturing team and determined the best remedy will be to recut/retool the few cavities that form these parts within our steel molds in an effort to not sacrifice any degree of quality or functionality. Our manufacturer tells us it should take about 3 weeks to retool the few cavities. (Please know we’re pushing everyone as fast as we possibly can.) This process of refining our molds is a critical step in manufacturing Stickybones to the highest quality possible. We’ll begin the production run (making the actual Stickybones) for our backers just as soon as all the Stickybones steel molds are fine-tuned and finaled. We hope this process will go smoothly and without any more hiccups that add to production time. All of our other products/items (Fly-Rig, Performance Stages, Pose Plates, Magnet Wands and packaging) are well on their way to being done and will be waiting in the wings for Stickybones to finish.

Below is a little sneak peak of a few of the very first molded parts still in their “rough” state prior to notes and tuning and are not in final colors. These were the first parts we injection molded in our steel molds. (The top photos are the toes (without cap) and the bottom is the upper leg and lower leg popped together.)

More pics coming soon when the second round of trial samples are completed next week.

The Next Step: We’re scheduled to complete the official second trial round of sample parts next week and will inspect and test them to ensure our notes were implemented, and specifications are being met. At that time, we’ll determine which parts need another round of mold notes, and will give those notes accordingly. The few parts being redone are scheduled to be completed about three weeks later, at which time we will put those through inspection and testing as well.

Sat Apr 8 '17 Announcement

over 7 years ago

– Sat, Apr 08, 2017 at 06:05:02 PM

Mar 8—Part 1 of 3

Forenotes:

- If you like more frequent updates, follow us on our newly minted Instagram.

- Don't worry about updating your address until you receive an email survey from us.

Hello! We have lots of progress to share—Let's jump right in!

The Fly-Rig

The Big News: Our toolmaker has successfully implemented the previous set of notes derived from the first samples. We’ve now begun inspecting and testing the official second trial of sample parts—and we are very happy with them. (See them below.) (Note: The final color will be upgraded for free to chroma key green. The requests for this still continue to roll in!)

The Next Step: We are very close to finalizing the Fly-Rig molds! We have a few minor (but important) mold tweaks to be done. Once those are implemented, we should be able to shout “FINAL!” (Will we really shout “Final”? Or will we just proclaim it in enthusiastic indoor-voices? That’s yet to be determined.)

Pose Plates

The Big News: All of our Pose Plates are machined! We snapped these photos of them in their raw steel glory at our metal fabrication partner’s machining facility.

And even bigger news? They have already been shipped to our powder coating partners! We’ve had 100 of them run as a trial through the painting process—and they look gorgeous. Below, you can see the very first batch of Pose Plates powder coated in a beautiful, shiny chrome. (And two dorks on the bottom left who are happy with the results.)

The Next Step: We’ve given the go-ahead to continue painting the rest of the Pose Plates. Once painting is completed, they will be shipped to our Stickybones manufacturer, who will place one Pose Plate into each box of Stickybones.

Performance Stages

The Big News: The Performance Stages have been machined! We have visited our machining facility and inspected the raw, unpainted Stages in person… they look great and we are very happy with the quality!

The Next Step: We are now shipping them to our powder coating partners who will begin painting them within the next few days.

Thu Mar 9 '17 Announcement

almost 8 years ago

– Thu, Mar 09, 2017 at 09:53:19 AM

Greetings!

We have a short and sweet (but exciting) update. We’d like to share great news that we’ve reached a big manufacturing milestone—We’ve received our first Fly-Rig manufactured samples! This is means the Fly-Rig steel molds are about 95% done. Currently, we’re inspecting the first sample parts and giving notes to the mold-maker for any needed adjustments. Once the mold-maker has implemented the notes, we’ll make a second run of sample parts and repeat our testing process before giving another round of notes. We will repeat this process until we have perfectly honed in on our final feel and functionality.

Pictured Above: The first-run Fly-Rig samples fresh from our steel molds! The samples are white because our Chroma-Key Green color is still being processed.

In the above image, you can see the upgraded Fly-Rig Base and Insert-Rod we’ve engineered to be stronger and more convenient—it’s made with a combination of materials for a snug, snap-to-fit feel. No more twisting of screws—just pop-in and go. Easy-Peasy! The Fly-Rig comes with two Insert-Rods. One plugs into the base as seen above and the second Insert-Rod is used to connect Stickybones to the other end of the Fly-Rig for fast, dynamic mid-air posing. You can pre-order your Fly-Rig HERE.

The Stickybones’ first manufactured sample parts are nearly done.

We expect to see them in about a week and we will let you know as soon as we get them. (The Stickybones figure has many more complex parts than the Fly-Rig, which is why we’re seeing the Fly-Rig samples first.)

Please follow us on Instagram!

https://www.instagram.com/stickybones.pose/

We’ve just started a Stickybones Instagram account where we’ll post some photos in between official campaign updates. Head over now to see some packaging prototypes as well as the Magnet Wand prototypes.

CHEERS!

Team Stickybones

Tue Feb 21 '17 Announcement

almost 8 years ago

– Tue, Feb 21, 2017 at 07:25:52 PM

Feb 21—Part 3 of 3

Shipping/Fulfillment:

We now have backers in 91 countries!

- Calculating shipping carriers and costs to 91 countries for a wide variety of orders is no simple task. We’re working on this now with excellent guidance from fulfillment experts. When the calculations are done, we will send you a survey to get your mailing address, collect your final shipping fees, and lock in your color choices— (meaning Standard vs. Limited Edition Spark Blue.)

- We’ll try to ship Stickybones in the order we received your contribution. To help us with this, please fill out the mailing address survey, choose your colors and pay your shipping fee as soon as you receive the email. (We’ll post another update when surveys have gone out.)

- International backers— Please remember you’ll be required to pay import taxes (VAT in some places) to your country upon receipt of Stickybones. Each country’s tax rate is different and will vary.

So WHEN should Stickybones start shipping?

The shipping time-frame estimate is very much at the mercy of when the molds are complete. Due to the Stickybones steel molds taking longer than the mold-maker anticipated, we are certain we will not be able to ship in March—depending upon when the molds are completed and when you ordered, delivery of your Stickybones could likely push into May. We know this has taken longer than we all anticipated and that you wish you already had your Stickybones in your hands putting it in the coolest poses imaginable! We understand this, which is why we so greatly appreciate your patience, encouragement and support as we continue to push the petal-to-the-metal during the wild and wonderful process of taking something as unique and precise as Stickybones from an idea to a final product, destined for global shipping.

Thank you for being such wonderful and supportive backers. For those of you who have been with us from the very beginning of this exciting journey—you are a special group we hold very dear. And we’re getting so close to the end! For those backers who have joined Stickybones community more recently—Thank you and welcome! Soon, you’ll be among the first people in the world to get Stickybones and we are looking forward to seeing what you and every other backer creates with this new and exciting product!

Sincerely, Team Stickybones